Industrial fans are high capacity, uninterrupted efficient systems. Industrial fans are designed and installed considering the expectations of the environment and future process requirements. ERF Group works as the most reliable company that manufactures and supplies industrial fans.

In order to produce a solution, it is enough to specify the need. Internet access or telephone access can be provided at any time of the day to obtain information. Company experts can provide technical support and product supply services in the shortest time possible.

The technological products referred to as industrial fans provide healthy and clean air to the environment they are in. Industrial fans used in businesses create pressure within themselves and change the direction of air flow in the environment. ERF Group, which continues its production activities with completely domestic capital, works as a pioneer in industrial fan production.

Fans produce high pressure and change the direction of dust, smoke and dirty air in the facility. In this way, unwanted air can be removed from the environment. Installation is carried out by selecting fan features according to industrial area capacity and user expectations.

Fan installation is carried out as a result of the on-site inspection and evaluation by ERF Group experts. It is available in 1000, 200 cubic meters/h, 23000, 160,000 cubic meters/h production features. These industrial fans provide service up to 1200 and 2000 mmss pressure expectations.

The fan types used in businesses are high capacity products. They must be installed after being evaluated by professionals. Otherwise, they may not meet expectations.

In industrial areas, the fan type is selected according to the installation location and usage needs. The fan types used in chemical plants are specially produced and offered for use. Industrial fan types;

Each of them is the most efficient product in its capacity and usage area. In addition, industrial axial fans are divided into two groups. They are produced as guide vane axial fans and propeller vane axial fans.

Fan groups always stand out among ERF Group products. All products are produced and offered for use in a way that provides high quality and maximum efficiency.

Chemical plants are highly sensitive environments and the fan group to be used must be evaluated in this direction. The type of fan used intensively in chemical plants is the electrostatic filter. These devices have the ability to purify the air from smoke, unwanted odors and oily air.

The air that is rapidly absorbed in the system is sent to the metal filter at the front. Metal filters are cleanable systems. Here, the air that is rapidly cleaned of particles by high-pressure electrostatics is ionized. The particles that are ionized and charged with positive electricity are sent to the collector surface.

There are both positive and negative charges on the collector surface arranged at equal intervals in parallel. Here, the positively charged system repels the particles and the negatively charged system attracts and collects the particles. The filters are cleaned at regular intervals to ensure uninterrupted efficiency from the system.

Fan types used in chemical plants are selected according to need. Those in need can obtain product supply by receiving support from ERF Group experts. Fan types used intensively in industrial areas can also be used in chemical plants. Circulation fans are also used safely in chemical plants, bread ovens, and static paint ovens.

The expert determines where the industrial fans will be supplied and which fan should be used in which environment. The type of industrial fan to be used in chemical plants is planned and installed according to the characteristics and scale of the environment.

In the ventilation systems needed in chemical plants, first of all, it is necessary to get help from the ERF Group team. Installation can be done by choosing the fan type by making a joint decision. The company has gained user satisfaction by supplying fan types to many parts of Türkiye and the world.

It operates with its production facilities, which are completely run with domestic capital, and its professional team in the field. It also provides uninterrupted service by installing safe and high-function fan systems in chemical facilities. The fan system sucks in the air with the pressure it produces and throws it out.

Industrial fans are used in many areas of life. Fans are used safely in large-scale facilities. Industrial fan usage areas;

Factories can be counted as paint shops. Industrial fans, which have a wide range of uses, are vital technological products. Fan systems are produced using electrical energy as their working principle.

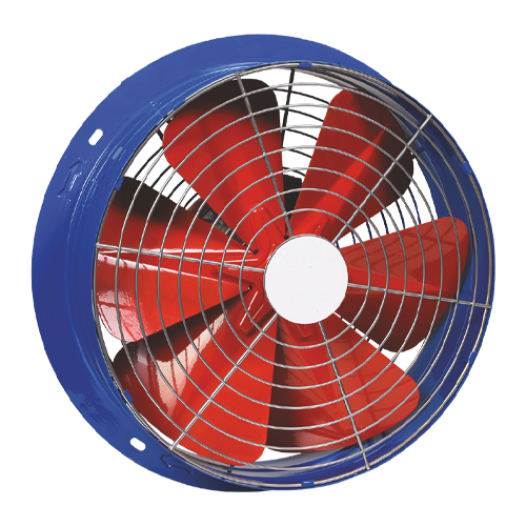

Industrial fans are products that are manufactured for special purposes and used according to the needs. There are radial, axial, snail, flug and cell types. Depending on the user's needs, installation location and purpose, there are also types defined as wall type, channel type, roof type and cell fans.

Wall type fans are generally used as axial fan groups. They are products that can be mounted on the wall. The body structure is manufactured in accordance with wall mounting. It ensures that the dirty air sucked in through air ducts is discharged.

Cell fans have a motor and propeller system in a cabin. There may be filters in the cell as well as heating and cooling batteries. Air is discharged at a 90-degree angle in cell fans. Sound insulation can be made in the cabin and control can be achieved.

Duct type fans are the types of fans that are installed between two channels. Air is discharged by flowing linearly through the fan. They are mixed flow fans that can be used in both radial and axial features.

Roof type fans are systems that provide ventilation by being installed on chimneys and roofs. They provide horizontal and vertical air flow. The air entering from under the body is discharged from the side surface at a 90 degree angle.

Different types of fans can be used in chemical plants depending on the place and purpose of use. The cost of industrial fans with construction is high. However, they are highly efficient and long-lasting systems. Installation and service maintenance requirements are always done by professionals.

Corrosion-resistant fan systems are generally used in chemical plants. They are designed and certified according to international standards as specially produced products. The devices ensure the removal of unwanted gas, air and particles. Centrifugal fans can also be used in chemical plants.

Exproof fans that can keep flammable and explosive gases and dust under control are used safely. Chemical plants are areas that require high levels of control in terms of employee and system safety.

Expfoof fans are manufactured in accordance with ATEX standards. ATEX fans, which are manufactured and quality controlled, are offered for use with certification. The most suitable fan system can be installed by receiving support from ERF Group experts.

Chemical facilities are places where living conditions must be kept under high control. Fans are also used in businesses that use chemical products. Facilities are divided into classes and risk status and fan systems are planned.

There are points with high combustion and ignition properties.

Examples of textile factories can be given. Exproof fans are used to create safe living spaces in high and low risk areas.