Radial Fans are used on many machines and equipment, industrial facilities, residences, shopping centers, tunnels, mines, sports centers, warehouses, etc. They are ventilation devices that can be used in air suction and / or air blowing in places and almost all areas of life.

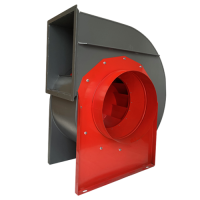

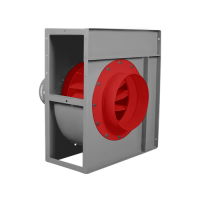

Radial Fans are also called Centrifugal Fans. Radial Fans blow the air at a right angle to the air inlet axis and activate the air with the centrifugal force effect created by the rotational speed of the fan impeller. It is possible to manufacture different blade and impeller structures for low, medium and high-pressure classes. High pressure and relatively low air flow models can also be called Blower Type Fan or Radial Blower.

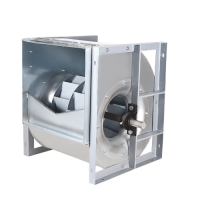

Radial fans can also be classified as Forward Curved Blades, Backward Curved Blades and Perpendicular Blades (Radial Blades) in terms of their impeller blade structure. Forward Curved Blades Radial Propeller Fans are mostly designed and produced with dense blades, Backward Curved Blades Centrifugal Fans and Centrifugal Blades Radial Fans are mostly designed and produced as sparse blades.

Radial Fans with Forward Curved and Close Bladed radial impellers do not operate at very high speeds. They usually work up to a maximum of 2000-2500 rpm. However, Backward Curved and Sparse Bladed Centrifugal Fans and Radial Bladed Fans can operate even at relatively higher speeds. When the manufacturing constructions are designed appropriately, they can go up to 4000-4500 rpm. Thus, while providing High Flow Rates and High Air Flow Rates, they can also meet High Pressure Losses. Radial Fan Blowers are also of this type.

Forward Curved and Closed Bladed Impeller Radial Fans are mostly used in systems with low and medium pressure loss. This type of fans are used in residential ventilation, Fresh air suction or blowing, Offices and Offices, Hotels, Business Workshops, Schools, Canteens, Cinemas, Factories, Garages, Parking Lots, Laboratories, Swimming Pools, Restaurants, Gyms, Theaters and many similar areas.

Backward Curved and Sparse Bladed Impeller Centrifugal Fans can be used in all systems with low, medium and high-pressure losses. This type of fans is more suitable for air suction containing particles such as dust, smoke, sawdust and oil. Since the blade gaps are sparse and spaced, it is easy to clean between the impeller blades. In industrial kitchens, in the suction of Hood Systems, in Carpenter's Workshops for Machining, Welding Fume extraction systems, in Air suction of systems containing Oily Air, In Paint Shops, Polish Shops, Boiler Rooms, Foundries, Furnace Workshops, as well as in all places where Forward Curved and Dense Bladed Propeller Radial Fans can be used.

Centrifugal Fans with Perpendicular Blades are mostly used in medium and high-pressure systems. These fans are mostly used in systems where material is transported together with air. Fans are easy to clean. Fan impeller can be produced with closed blades like other propellers or as open blades. Thus, the problem of material jamming between the blades can be prevented.

Radial Fans are produced in the form of volute/snail fans, as well as in fan types such as duct type fans, cell fans, roof fans. Forward curved and dense bladed radial impellers can be used inside Duct Fans and Roof Fans, as well as backward curved and sparse blade radial fan blades. At the same time, radial fans can be used in Cell Fans.

Radial Fans can also be produced as single suction and double suction. While the radial fans used in the form of volute/snail fans can be single-suction, the radial fans generally used in Cell Fans are double-suction ones. The use of single-suction radial fans by taking them into the cell is also a situation encountered in practice.

Radial fans can also be classified according to the way the fan is driven. The impellers of Direct Driven Radial Fans are mounted directly on the electric motor shaft and rotated. There are also models that are driven by a pulley and belt system from the other end of this shaft, by mounting the fan propeller on a shaft that is mounted on a stand. There are also models in which the impeller, which is connected to a shaft mounted on a stand, is driven by connecting the other end of the shaft directly to the electric motor with a coupling system.

Radial fans, which will be used in air intake at high temperatures, are generally preferred models with belt-pulley drive mechanism or coupling connection. However, in general, radial fans with direct coupled motors are much more preferred due to their economic nature. Direct Coupled Radial Fan Prices are lower than fans of other drive types.

In addition, radial fans can be classified according to the type of raw material from which they are produced. Radial fans, which are generally produced from ST37 or ST-52 Black Sheet material, can be produced from Stainless Sheet materials, Galvanized Sheet materials, as well as Aluminum Casting material. Radial fans can also be produced from PVC materials for acidic environments and for corrosive air intakes.

In radial fan requests, at least two values must be given to the manufacturer by the customer. The first is the air flow value that we expect the fan to suck or blow, and the second is the pressure loss value that occurs in the duct system to which this fan will be connected and that we expect the fan to overcome. The fan should be designed in such a way that it can give the desired air flow by overcoming the given pressure loss value. In addition, in order to be able to choose a healthier fan, it will be very useful to give the purpose of use of the fan, the air temperature, the altitude of the location where the fan will operate, the type and level of particles that can be found in the air, and similar special values.

We would like to emphasize that we expect you, our valued customers, who are in search of Radial Fans for Sale, to contact our company in order to respond with our radial fans that we have produced with the most affordable price and the highest quality.