Ventilation motors are highly functional products that stand out with their working principle of creating a pressure difference and providing air flow. It can be said that ventilation motor prices vary according to the features of the product. At this point, after determining the needs of the users, they need to make a choice in line with these needs. A ventilation motor fan purchased in this way will continue to work without problems for many years.

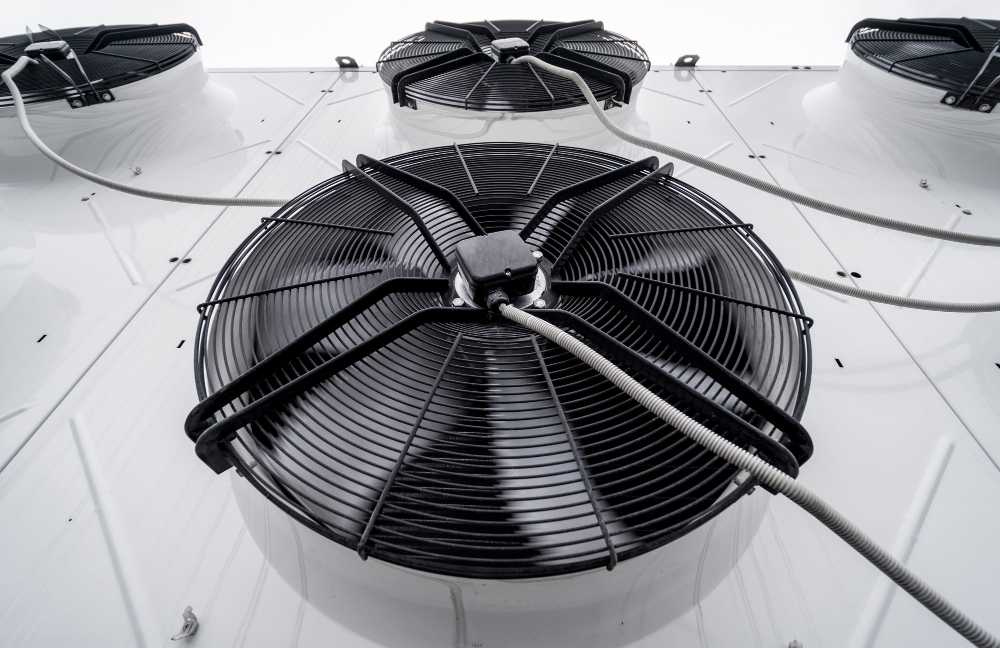

The ventilation fan blows the air in the environment depending on the propeller it has. Regardless of whether the air is hot or cold, it is a ventilation fan model that is actively used. In this way, the ventilation fan that provides air flow and cools or cleans the air meets the expectations when it is an industrial type. Ventilation fans are products that work by using electrical energy. The power received from this electrical energy is directly transmitted to the fan propellers. In this way, it has the ability to do work on the air by producing static and kinetic energy.

Ventilation motor fan; is one of the systems that helps to throw unwanted dirty, hot or cold air out of the closed area. While this air passing through the ventilation ducts is replaced with clean air, it is also pulled back into the environment. In this way, while hot, cold or dirty air is removed, clean air enters without any problem. Ventilation fans are generally very suitable for use at the entrance of ventilation ducts. The areas where ventilation motors are frequently used include places that need intensive ventilation such as parking lots, hospitals and shopping malls. Since it is not very easy to access clean air in these areas, the ventilation fan meets this need.

Ventilation fan types may vary from one another. These different fan models are listed as follows:

When choosing a ventilation motor, the calculations must be made very accurately. There are certain fans that can be selected for areas such as offices and small kitchens. However, in larger scale businesses and areas that serve more people such as gyms, fan selection requires very serious engineering calculations.

When choosing between ventilation fan types, the features of the facility where this product is used are very important. These features can be considered as determining factors when making a choice. The working conditions of the facility, whether the fan will work non-stop for 24 hours or will be activated at certain times of the day, directly affect the fan selection. In addition, all factors such as the air pressure rate, air flow rate, the number of devices located or operating in the space and the number of people in the space where the ventilation fan will be used must be taken into consideration. The number of people working in the area where the fan will be used is a guide in which product to choose.

Ventilation fans should be preferred with electric motors suitable for their power. It may be advantageous to choose EFFI type electric motors that operate with very high performance in large areas. After calculating the pressure losses in sections such as vents, shutters, channels, filters, static pressure should be determined. For ventilation fans that will operate at high temperatures, it is recommended to use winged dampers. Choosing this ventilation fan from reliable and competent companies will help you stand out.

The amount of air pressed or sucked by the ventilation fan can be varied according to some changes. By changing the speed of the fan, the type of the fan blades can be controlled by the fan blades and can be adjusted using the blades or at the fan outlet. It is also possible to control the fan speed using dampers. In this way, the fan can operate with lower or higher air movements at the desired time intervals.

Regular maintenance of the ventilation motor is extremely important. Users who want to get efficient service from the used fan for a long time should have these fans maintained correctly and regularly. Since the ventilation fan channels work with constant air pressure, they are very prone to dirt. Therefore, regular maintenance should be done to prevent dirt accumulation. In addition, the fan belts should be checked at certain intervals. The motor fan bearings are also among the places that should be checked. If the ventilation fan needs motor oil, it should be lubricated. Since dust and dirt formations are very common in the fan propellers, it is essential to clean the fan propellers regularly.

The factors to be considered when choosing a fan are as follows:

Ventilation motor prices vary depending on each company, brand and quality. At this point, the important thing is to determine the needs when purchasing a ventilation motor. In line with these needs, the required ventilation fan prices can be compared and a decision can be made. Another point to consider when choosing a ventilation fan is the company selection. Giving priority to quality in company selection is essential to gain advantage in the long term.

In this sense, ERF Group appears before you as a professional company that provides production at high quality standards. Based on its long-term experience, the needs and demands of its customers are its priority. Accordingly, ERF Group, which continues to grow and develop every day, provides you with privileged service with its long-lasting and durable ventilation fan models while meeting expectations. ERF Group guarantees you to reach clean air by using the opportunities offered by the latest technology. You can reach us immediately by using the contact numbers on our website to experience ERF Group quality.